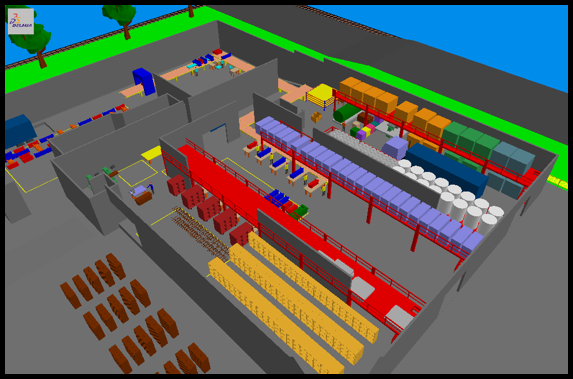

Simulation of industrial processes

PRODINTEC uses a complex system analysis and design tool that simulates the behaviour of a system in various scenarios and analyses possible changes and their consequences before implementing them. By means of these simulations and process analyses, we can check the lay-out, calculate the resources required, optimise the flow of materials, balance production lines, optimise stock levels, analyse logistics strategies, optimise planning systems, manage queues...

We can also design a new plant lay-out or redesign an existing one with a view to achieving an optimal configuration that will reduce wastage (operations that do not contribute added value) linked to overproduction, waiting time, transport, processes, inventory, movements, defects...

Work station simulations result in the detailed analysis of work stations and make it possible to optimize certain parameters such as distances and the location of resources from the point of view of ergonomics. PRODINTEC uses this tool to analyse and validate new processes without having to set up pilot work stations, to perform trials on the operation of a manual process or work station, train workers and reduce costs and time (time to market and time to volume).